One aim in 3D printing is to manufacture larger artifacts and stretch the limits towards high volume production. The opposing trend is connecting several technologies and needs to create the tiniest possible objects and machines.

1. Fiction and reality

Science fiction has often succeeded to describe future 30-50 years forward. Today we are experiencing for example cybernetics, exosceletons and robots that were predicted during 1980’s.

In movie Fantastic Voyage (1966) a submarine was shrunken to microscopic size and injected into blood stream with a small crew. Similar idea was presented in the french animation serie Il était une fois… la vie.

Now, 50 years later, these ideas are reality (without the crew, though) using special applications of microfabrication. Microfabrication, or micro-prodution, is the process of fabrication of miniature structures of micrometre scales and smaller.

Unimolecular submersible nanomachines (USNs) have light-driven motors powered by ultraviolet light, and can be created with just 244 atoms. The motors can run at more than a million RPM and move almost 25 mm per second – the fastest-moving molecules ever seen. Source: Kurzweil.

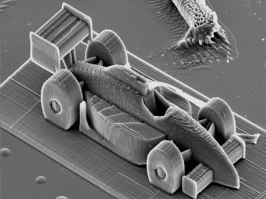

Very small scale 3D printing, the size of a grain of sand, has been demonstrated in several experiments. A 285 µm long race car was 3D-printed at the Vienna University of Technology and three-dimensional photonic crystal of cubic symmetry by nanoscribe.

Images: Vienna University of Technology (left), nanoscribe (right)

2. Innovation opportunities

When an object is made very small, it must have excellent mechanical and other qualities. In addition three other innovation opportunities become very interesting:

- Information,

- Biology and biomimicry

- Swarms.

2.1. Information

A very small machine can be extremely efficient in collecting real time information with sensors. It can go to exact locations in complex structures, such as human body, building or machine. Also it can receive information and instructions. Information is needed to enable interaction.

2.2. Biology and biomimicry

Nature is the master in building very small and efficient structures and processes. In building very small machines we can gain inspiration from biological structures but also use the actual biological mechanisms for example for sensoring, movement and energy production.

2.3. Swarms

Swarms are groups of machines or robots that collaborate. There are several examples showing the miraculous things that a collaborating swarm can do, such as building or playing together (TED example). A swarm of very small machines can be effective, intelligent, invisible and resilient.

Swarms can be controlled in different ways. Recently Purdue University researchers developed a method to use magnetic fields to independently control individual microrobots operating within groups, similar to how ants work.

Image: Swarm of small robots. Source: WSJ

3. Microfabrication & the making of tiny objects

We are talking about objects that are invisible to eyes. They are smaller then the dot at the end of this sentence. How do you make such objects and machines?

Our technology toolbox has, for example:

- Commercial nano scale 3D printers

- 3D printing processes for nanoscale (different materials, electronics, etc)

- Biological engineering, microbotics and biomimicry

- New functional materials, based on biological processes

- Mechanical engineering

- Sensors

- Information processing and communication capabilities

- Intelligent software, swarm management

Miniaturization of machines presents challenges in many areas of science and engineering, such as physics, chemistry,materials science, computer science, ultra-precision engineering, fabrication processes, and equipment design. It is also giving rise to various kinds of interdisciplinary research. Source: Wikipedia.

Controlling the basic additive manufacturing process for metals is already challenging. The manufacturing and operating processes get far more complicated when we need to handle also biological processes and information processes.

Molecular 3D printer, or 3D printer for chemicals can print billions of possible compounds. The vision for the future is that anyone who needs a specific small molecule can essentially print it out from their computer.

4. What new functionality can be created?

What are the new applications and functions we can provide with microfabricated machines?

We have created some first useful applications, such as hydrophobic surfaces. However, we are dealing with a major science fiction type of imagination challenge. The availability of new technologies, materials and capabilities initiate profound mutation of engineers’ way of thinking. We simply must learn to think and design in new ways. And get science fiction people onboard.

For example biological engineering is an emerging discipline that encompasses engineering theory and practice derived from the science of biology, just as mechanical engineering is rooted in physics. An example of this is cyber insect, where the idea is to insert micro-systems at the pupa stage, when the insects can integrate them into their body, so they can be remotely controlled later. What are the applications of a cyber insect?

Application areas for very small machines can be found in medicine, environmental protection, and the process engineering industry, all of which need small, reliable systems that work as quickly and accurately as lab-on-a-chip. For example, microfluidic channels are required to safely move small volumes, with functioning components such as filters, stirrers, etc. in them. Source: industrial-lasers.com.

5. Keep wondering

The microscopic world of microfabrication, 3D printing and 4D printing is a huge research, manufacturing and business opportunity. It calls us for super efficient multidisciplinary innovation collaboration between traditional engineering, bioengineering and information sciences. It is a magnificent imagination challenge!

6. Further sources

The following links provide ideas and examples in the world of 3D printing and microfabrication. Please send me further links to update the resource.

Small machines that fly

- http://en.wikipedia.org/wiki/Micro_air_vehicle,

- http://en.wikipedia.org/wiki/Nano_Air_Vehicle

- http://www.thisiscolossal.com/2013/04/thebionicopter-a-robotic-dragonfly-by-festo/

- http://www.bbc.co.uk/news/science-environment-22380287

- http://micro.seas.harvard.edu/

Small machines that walk

- http://www.popularmechanics.com/how-to/blog/3d-printed-biobots-will-crawl-through-yourbody-targeting-toxins-14735565;

- http://www.nbcnews.com/technology/mini-bio-bot-walkswhen-its-rat-heart-cells-beat-1C7099426,

- http://www.gizmag.com/kinect-controlledcockroaches/28108/

Small machines that sense

- http://www.3dmpconference.com/3d-medicine-printing-conference/adding-biomolecular-recognition-capability-to-3d-printed-objects-4d-printing-presented-by-celine-a-mandon-3d-fab-universite-lyon-1/

- http://www.kurzweilai.net/new-nanomanufacturing-technique-for-extremely-high-resolution-imaging-biological-sensing

New materials

- http://www.medgadget.com/2013/04/oxford-creates-new-type-of-3d-printed-replacementtissue.html,

- http://www.3dprinter.net/print-me-invisible-with-metamaterial,

- http://web.mit.edu/3.042/team1_08f/project.html,

- http://www.ted.com/talks/lee_cronin_print_your_own_medicine.html

Events

- Bioprinting conference: http://www.3dbioprintingconference.com/program/