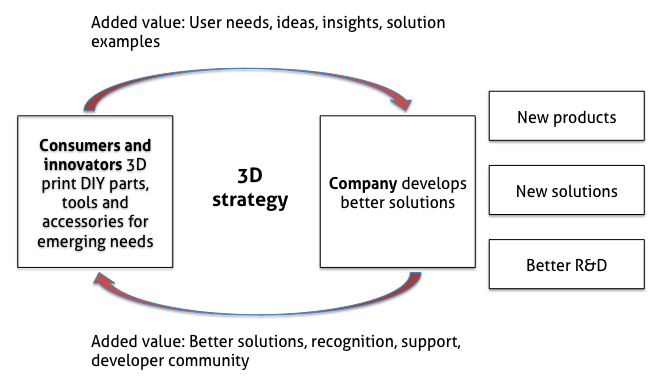

3D printing is a promise for radical new concepts, products and functionalities that have never existed before. Unfortunately only less than 1% of us can imagine truly new things. We are mostly copying and variating earlier ideas.

So how can we find the truly new products and future-proof solutions ? Here are some strategies for this.

Innovation can take place at component or system level. The novelty can be considered by the impact it has (incremental, radical).

Figure 1. Dimensions of innovation by Joe Tidd.

In this article we talk about exploration for new products that are made possible by 3D printing. Exploration is the activity when the organisation seeks future product directions and opportunities.

Grounded vs. disruptive exploration

Grounded exploration emphasizes systematic development and logical improvements to products. Disruptive exploration is based on “soft” and creative practises, such as pure creativity, allowing unexpected combinations, and taking higher risks. Grounded exploration may be more common in established engineering companies and disruptive exploration in agile start-up companies.

There are always more options than can be explored and implemented. It is difficult to know which direction to take and where the markets and competition will be. The explorer is in similar situation as an astronomer trying to see distant stars – it is difficult to see far due to distance or other disturbing factors (Figure 2).

In grounded exploration the designer sets first the criteria for exploration and then studies the opportunities. In disruptive exploration the criteria for new products are set later when the opportunities are perceived.

Figure 2. The problem of identifying the right opportunities

Logical vs. non-logical

Logical approaches lead to predictable innovations and can be deducted by looking at the premises, user needs, competition and technology advances. Example activities:

- Extend and improve the products to predictable directions, for example based on user feedback.

- Update the applied design tools and technologies.

- Change the product strategy according to user or business needs.

- Apply user-centred development processes.

- React to competition.

Non-logical approaches lead to ideas and innovations that are not obvious by looking at existing knowledge or premises. Non-logical approaches emphasize designers’ ideas, inspiration and unexpected technology combinations. The areas explored can be in conflict with the results from logical thinking. Example activities:

- Extend the concepts or features to non-predictable directions

- Try unknown or unproven solutions.

- Challenge the knowledge from market research.

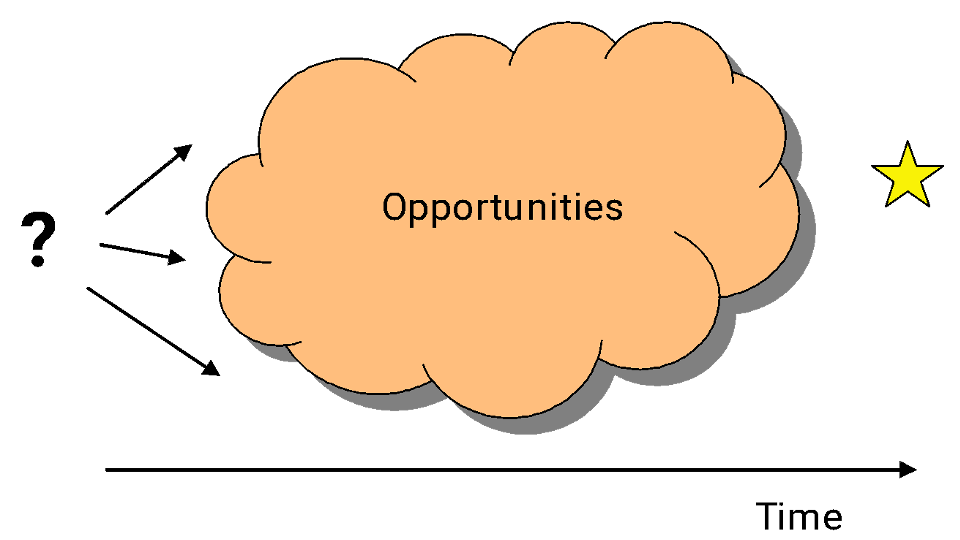

Target oriented vs. open ended

Target oriented approaches aim to fulfill a pre-defined goal, such as certain features, market share, price, design or customer need. The activities as a whole establish an exploration ”lense”. The pre-defined goal is the focal point for the lense. Example activities

- Explore only ideas that support strategic (primary) goals

- Fix errors.

- Add features.

- React to feedback.

- Design for synergies across features

Figure 3. Target oriented exploration

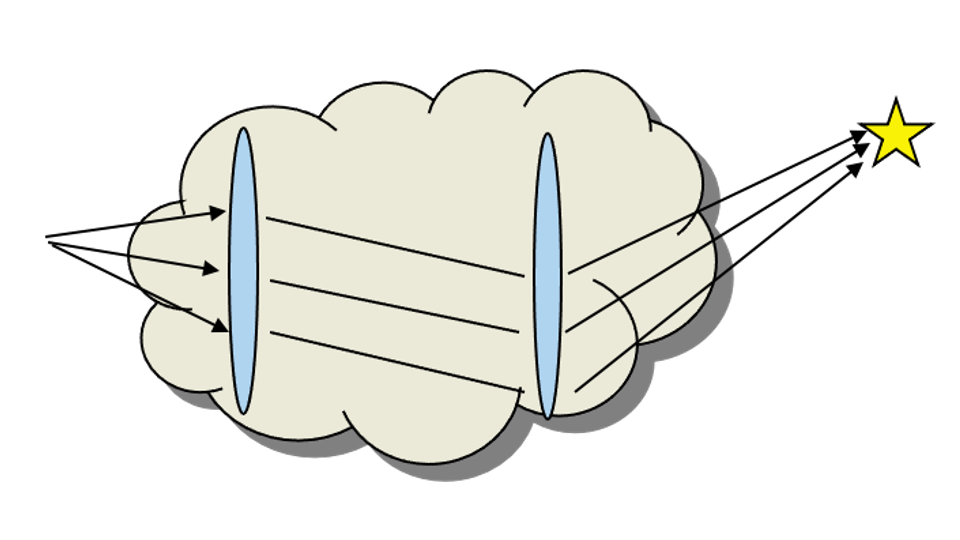

Open ended approaches. In this approach the mission is simply to find new, without pre-defined limitations and with minimal guidance. Existing opportunities and unexpected findings are seen as “lenses” that lead the exploration towards undefined goal. The target comes visible when different combinations are tried and studied. By applying ”lenses” at different situations during exploration, different objects and possibilities come visible. Examples

- Explore with non-strategic (secondary) goals

- Maximize the generation of new ideas and combinations of ideas. Focus on quantity rather than quality.

- Make design perspectives (Where we are heading?) and take perspectives (Where are we now?)

Figure 4. Exploring the unknown with opportunities

Rational vs. irrational

Rational approaches look to directions and solutions that make sense and can be justified with business goals, expertise, or data. This approach is similar to logical approach, but the emphasis is in “common sense” and intuitition – “We know there is something”. Team’s expertise and quiet knowledge play important role.

The concept of gravitational lenses clarifies the situation: you have observations indicating that something is behind the obstacles, but currently you can observe and explore only second hand indications. Examples activities:

- Extend the ideas with known and justified use cases and ratioanl details

- Assume emergence of certain trend, technology, customer need or user behaviour

- Ignore some known limitations, uncertainties and risks, but with a good reason

Figure 5. Gravitational lense. A gravitational lense is formed when the light from a very distant, bright source (such as a quasar) is ”bent” around a massive object (such as a cluster of galaxies) between the source object and the observer. Souce: Wikipedia

Irrational approaches emphasize ideas that stem from non-rational user needs or simply playing with available technology and design options. Although people are capable of rational thinking they very often act irrationally or have irrational needs. For example, market research may reveal expectations or latent needs that can’t be explained by rational analysis.

For example, explore solutions that emphasize ”beauty”, “joy”, “happiness”, “showing off” that are difficult to explore, model and manage with rational mindset. This approach requires high degree of creativity and freedom, good modeling tools, but still proper understanding of the doable vs. not-doable elements. For example:

- Apply irrational (not justified, not predicted by theory, not logical) elements in the ideas, such as playfulness and “wov”. Consider also very short lifetime vs long lifetime of a product idea, since these lead to different concepts.

- Work with artists, people with creative talents, lead users, etc.

- Explore beliefs, religions and other non-scientific areas that guide people’s behaviour and markets.

Incremental vs empirical

Incremental approach aims to add new elements into existing products and systems, i.e it studies what is missing part. Incremental exploration is maybe the easiest and safest option to go, but will not contribute to a new product strategy. In this approach we accept also negative increments, i.e. changing the concepts by removing existing elements.

Figure 6. Incremental approach

Examples:

- Which functions / elements could be added to existing products and systems?

- Which functions / elements could be removed from existing products and concepts?

- Which features could be combined or integrated?

Empirical approach

Empirical or new-creating approach aims to define fully new strategy or direction for product innovation and concepts. The work of a designer resembles the work of an artist who applies different kinds of methods, technologies and techniques in a flexible manner in a process of appreciation, action and re-appreciation, constantly reflecting on his own work. The empirical approach designers rarely follow the methodology prescribed by normative theories.

Figure 7. Empirical approach

Examples:

- What could be created from the given elements?

- Which new user functions, features or designs could be proposed?

- Focus on outliers! Outliers are ideas and concepts that seem not to fit with ”proper” ideas and are not compatible with the mainstream solutions.

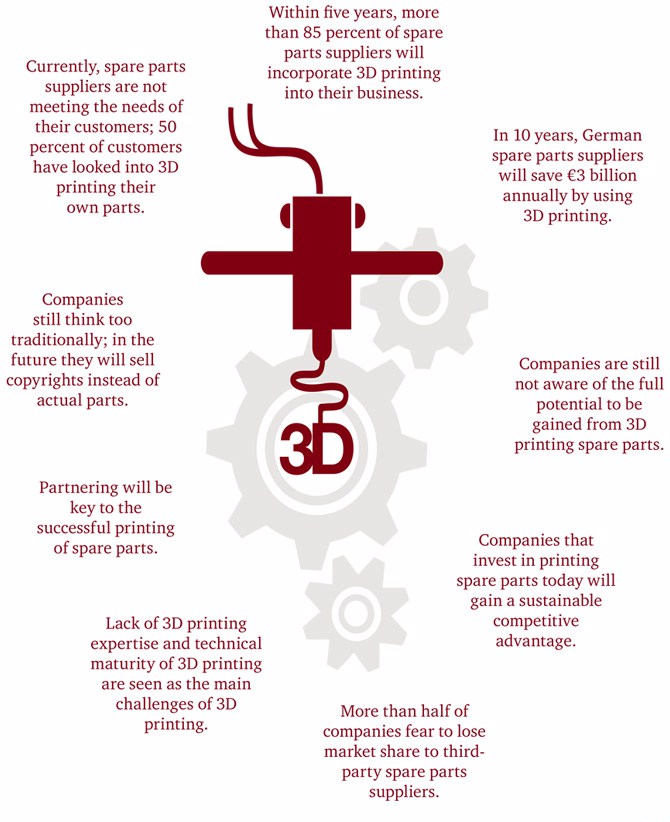

Strategies for exploration

We can’t directly see to the future. It would be nice if we could. The future is hidden beyond time, trends, technology advancement and unexpected events. Fortunately we can see signs of the future everywhere around us, such as megatrends, trends, silent signals, outliers and research results. Astronomers have similar problem when they try to see galaxies and black holes that hide behind massive systems in space.

Here are four strategies to apply when identifying the opportunities for future products or systems.

1. Lenses to future

Use exploration ”lenses” as descibed in the sections above. Try to see the new opportunities and accept unexpected findings.

2. Wind Approach

Imagine you try top navigate straight from west to east and there is strong north wind. In order to reach the destination you actually need to aim to north east. This gives a different route and new parameters for the exploration.

The Wind Approach is a method for product innovators seeking future product ideas by embracing the unexpected and venturing into uncharted territories. Inspired by the way a navigator adjusts their course when faced with adverse winds, this approach challenges traditional thinking and encourages innovative solutions to emerge. By intentionally deviating from the conventional path, the Wind Approach opens up new dimensions of exploration and unlocks a plethora of exciting possibilities.

Methodology:

- Defining the Destination: Start by identifying the overarching goal, problem or product idea you aim to solve. This represents the ”destination” you want to reach through innovation.

- Mapping the Traditional Route: In the absence of any constraints or challenges, chart out the most straightforward route to your destination. This represents the conventional approach to innovation.

- Identifying the Wind: Introduce a disruptive element or constraint that mimics the strong north wind in the analogy. This could be a limitation, a constraint, an opposing trend, or an unconventional perspective.

- Adjusting the Course: Just as a navigator adjusts their course to navigate around the wind, deliberately deviate from the traditional path. In response to the introduced constraint, pivot your perspective and consider alternative directions.

- Finding the North East: Instead of simply overcoming the constraint, use it as a guide to explore new destination, new routes and dimensions. Like aiming for the north east in the face of a north wind, seek out unconventional ideas and opportunities that arise from accommodating the constraint.

- Exploring New Parameters: The Wind Approach prompts you to redefine the parameters of your innovation exploration. As you navigate around constraints, you might discover unexpected intersections between ideas, designs, materials, industries, or technologies. This can lead to the creation of entirely new product concepts.

Possibilities and Benefits:

- Divergent Thinking: The Wind Approach fosters divergent thinking by pushing innovator to question assumptions and break free from linear thought patterns. This can lead to solutions that might not have been considered otherwise.

- Cross-Disciplinary Insights: Embracing constraints can open doors to collaborating with experts from diverse fields. The process of navigating constraints often involves borrowing insights and techniques from unexpected sources, fostering cross-disciplinary innovation.

- Unique Value Propositions: By embracing challenges and constraints, you can arrive at product ideas with unique value propositions. These ideas might solve problems in ways that resonate deeply with users or disrupt established markets.

- Innovative Problem-Solving: The Wind Approach encourages creative problem-solving, as the need to circumvent constraints can lead to elegant and unexpected solutions.

- Market Differentiation: Products conceived through the Wind Approach are likely to stand out in the market due to their unconventional nature. This differentiation can lead to stronger market positioning and a competitive edge.

- Innovation Mindset: Continuously applying the Wind Approach can cultivate an innovation mindset within teams and organizations. It encourages a culture of adaptability, resilience, and open-mindedness.

3. DreamForge approach

DreamForge is a design methodology that harnesses the power of AI-based image generators, or any other system that amplifies the exploration space digitally, to create visually stunning and highly intricate product concepts. Unlike traditional design processes that rely solely on human creativity and constraints, DreamForge taps into the limitless potential of AI to generate products that transcend the boundaries of reality. This methodology leverages advanced machine learning algorithms to produce designs that are rich in complexity, detail, and innovation.

Figure 8. Product exploration with DreamForge. Image by Midjourney.

Key Steps:

- AI Training: The DreamForge methodology begins with training AI models on an extensive dataset of existing 3D designs, art, and various visual inspirations. This enables the AI to learn patterns, styles, and artistic elements. This step is not always needed, since generative AI:s may have sufficient data already in place.

- Creative Seed: Users provide a basic idea or concept as a creative seed to guide the AI’s initial design generation process. This seed could be a vague description, a set of keywords, or even an abstract image.

- AI Design Generation: The AI takes the creative seed and generates a diverse array of design concepts. These concepts can be wildly imaginative, incorporating elements that human designers might never conceive.

- Iteration and Refinement: Users review the generated designs and select the ones that resonate with their vision. They can provide feedback to the AI, which then refines subsequent design iterations.

- Customization: Users have the option to customize and fine-tune the selected design, adjusting specific details, scales, and features to align with their preferences.

Benefits of DreamForge:

- Unbounded Creativity: DreamForge unleashes a new level of creativity by producing designs that defy conventional boundaries. AI-generated designs introduce novel shapes, patterns, and aesthetics that push the limits of imagination.

- Efficiency and Speed: Traditional design processes can be time-consuming and iterative. DreamForge accelerates the design phase by rapidly generating a multitude of unique concepts, expediting the creative journey.

- Intricate Detailing: The AI’s ability to incorporate millions of intricate details and nuances results in designs that possess a depth of complexity that would be nearly impossible for a human designer to envision.

- Idea Exploration: DreamForge is a powerful tool for exploring design ideas that may have been overlooked or deemed unfeasible. Users can visualize concepts they might not have considered otherwise.

- Personalization: Users can inject their personal preferences into the design, ensuring that the final product reflects their unique style and taste.

- Innovation Catalyst: DreamForge serves as a catalyst for innovation, inspiring designers, artists, and creators to break free from conventions and explore uncharted territories of design.

4. VisioForesight approach

VisioForesight approach is a scenario planning method that helps explorers anticipate and navigate a range of potential product futures. By crafting detailed stories of plausible yet diverse outcomes, scenario planning empowers decision-makers to be proactive, adaptable, and ready for whatever product opportunities tomorrow may bring.

Methodology

- Define X and Y Axes: In the context of business scenarios, the X and Y axes often represent two key dimensions or variables that influence the scenarios. Similarly, in the context of product exploration, you could define two axes that capture essential aspects of the product. These axes could be factors like ”Functionality” and ”Aesthetics,” ”Complexity” and ”Simplicity,” or any other relevant pair of attributes.

- Explore the Four Fields: Once you’ve defined your axes, you can divide your scenario map into four quadrants, each representing a distinct combination of attributes. For example:

- Quadrant I: High Functionality, High Aesthetics

- Quadrant II: High Functionality, Low Aesthetics

- Quadrant III: Low Functionality, High Aesthetics

- Quadrant IV: Low Functionality, Low Aesthetics

- Applying this Approach to Product Exploration: Let’s say you’re designing a smart medical device. You could use the axes ”Innovative Features” and ”User-Friendly Design” to create your scenario map:

- Quadrant I: Device with Cutting-Edge Features and Intuitive User Interface

- Quadrant II: Feature-Rich Device with Complex User Interface

- Quadrant III: Visually Stunning Device with Simplified Features

- Quadrant IV: Basic Device with Limited Features and Usability

- Benefits: Structured Exploration: This approach provides a structured framework for brainstorming and exploring different product ideas based on specific attributes or dimensions.

- Idea Generation: By systematically exploring each quadrant, you ensure that you consider a wide range of possibilities and avoid overlooking potential ideas.

- Evaluation Criteria: The scenario map offers a way to evaluate and prioritize ideas based on the attributes represented by the axes. This can help in aligning product ideas with your overall design goals.

- Visual Representation: The scenario map provides a visual representation of the product landscape, making it easier to communicate and collaborate with team members and stakeholders.

- Informed Decision-Making: By mapping out different scenarios, you can make more informed decisions about which quadrant aligns best with your target audience, market trends, and business objectives.

- Holistic Approach: Considering both functional and aesthetic aspects ensures a holistic approach to product design, leading to products that not only perform well but also engage users visually.

- Diverse Range of Ideas: By changing the attributes on the axes, you can adapt the scenario map to different products and explore a wide range of design possibilities.

Conclusion

There are many avenues for finding future products. Some require systematic work and some are based on imagination. Maybe the best results are achieved by hybrid approaches, where both aspects are applied.

This article is a preview to a wider work that brings new tools to the creators of future products, especially to support the imagination challenge of 3D printing. Stay tuned!

All comments and feedback are highly appreciated!

Pekka Ketola, August 28, 2023