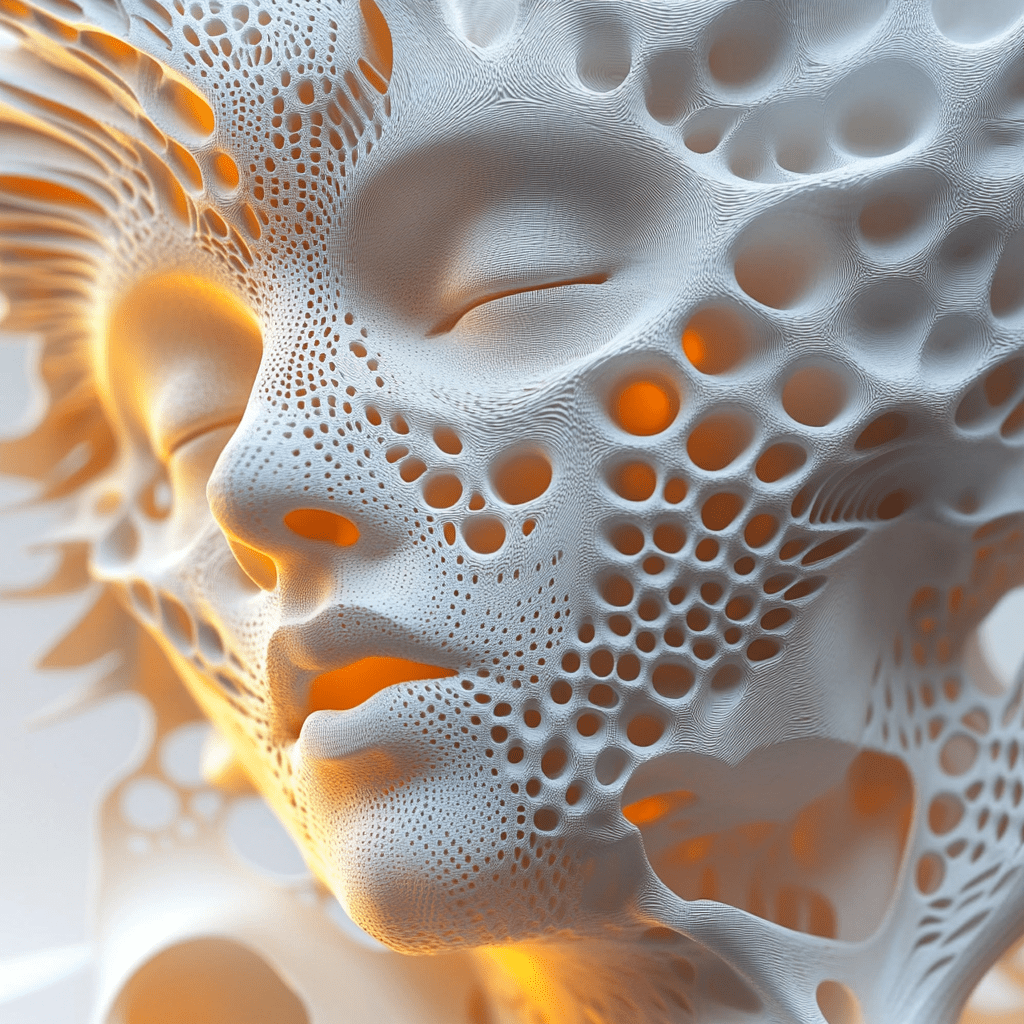

3D printing has numerous promising applications in healthcare, particularly in hospitals. This technology enables more personalized and efficient patient care while improving the quality of medical procedures. Let’s look at the present and the future.

Key Applications:

Anatomical Models:

With 3D printing, patient-specific anatomical models, such as those of the heart, kidneys, or prostate, can be created based on CT or MRI scans. These models help surgeons plan complex surgeries with greater precision, enhancing patient safety. They are also valuable for medical students and patients, as they provide a clearer understanding of diseases and human anatomy.

Patient-Specific Instruments and Implants:

3D printing allows the production of custom surgical instruments and implants tailored to individual patients. This is particularly beneficial when standard-sized devices are unsuitable, such as in gynecological instruments or orthopedic implants. Personalized implants improve fit, comfort, and treatment outcomes.

Surgical Planning and Training:

3D-printed models are instrumental in planning and simulating surgeries. Surgeons can practice complex procedures on these models, reducing errors and shortening operation times. Soft models even allow surgeons to feel the structure of organs, offering a realistic training experience.

Patient Communication:

Doctors can use 3D models to explain a patient’s condition and treatment plan. These models help patients better understand their situation, reducing anxiety and fostering trust in their doctors.

Innovative Medical Devices:

3D printing accelerates the development of new medical devices and prototypes. Bioprinting—printing biological tissues—is a particularly promising field that could enable the production of new tissues and organs in the future.

Education:

Medical students and surgeons benefit from 3D-printed models for learning anatomy and practicing various surgical procedures in a realistic and hands-on way.

Future Outlook

Although 3D printing is not yet a standard practice in hospitals, its potential is immense. As the technology evolves and costs decrease, its use in healthcare is expected to become more widespread. Hospitals can invest in their own 3D printers or collaborate with specialized companies to leverage this innovative technology.

Envisioning the Future: AI, Digital Twins, and Personalized Care

The future of healthcare is set to be transformed by the convergence of 3D printing, AI, and digital twin technologies. AI-powered digital twins are expected to create virtual replicas of patients, organs, or systems. These digital twins will allow doctors to simulate a patient’s unique medical profile, predict disease progression, and tailor precision treatments.

For example, digital twins of the human brain could revolutionize the understanding and treatment of neurological diseases. Meanwhile, AI-driven tools integrated into clinical workflows will enable faster, more accurate diagnostics and treatment plans, taking into account genetic, biological, and environmental factors for truly personalized healthcare.

Advancements in genomics, gene editing, and 3D bioprinting will further enhance these capabilities. The synergy of 3D printing with AI and precision medicine could lead to entirely new approaches in patient care, such as the creation of 3D bioprinted organs customized to match a patient’s genetic makeup.

Remote monitoring and telemedicine are also expected to benefit from these advances. AI-powered wearable devices and 5G networks will allow real-time monitoring and virtual consultations, even analyzing subtle changes in speech patterns or activity levels to detect signs of illness early.

As these innovations evolve, they will work alongside 3D printing to make healthcare more efficient, precise, and accessible, paving the way for groundbreaking medical advancements and better patient outcomes.

Sources:

- 3D Printing in a hospital: Centralized clinical implementation and applications for comprehensive care

- Sophisticated 3D modeling plays growing role in healthcare

- 3D printers in medicine

- 3D technology and precision medicine in the hospital sector

- The use of 3D-printed models in patient communication: a scoping review

- Introduction to Medical 3D Printing and 3D Printers for Healthcare

- 7 Stunning Use Cases For 3D Printing In Medical Field

- The Importance of 3D Modeling in Healthcare

- Anatomical Engineering and 3D Printing for Surgery and Medical Devices: International Review and Future Exponential Innovations

- Leading Barcelona Children’s Hospital Embraces 3D Printing

- 3D models for medicine

- The Future of Health: Innovations to Watch in 2025

- Personalised medicine and digital twins – the big trends in the future of healthcare

- Top Trends in Healthcare Tech in 2025 – How the Medical Industry is Adapting to a New, Better Tomorrow

- The role of Digital Twin in Healthcare – Current Trends and Challenges

- 5 Key Trends in Medical Animation – Predictions for 2025

- The Digital Twin in Medicine: A Key to the Future of Healthcare?

- Top 8 Telemedicine Trends and Technologies in 2025

- Digital Twins in Healthcare Market

- Could digital twins be the next revolution in healthcare?