Digitalisaatio, AI ja 3D-tulostus muuttavat tapaamme valmistaa ja kuluttaa tuotteita. Yrityksille tämä tarkoittaa uutta mahdollisuutta: valmistaa yksilöllisiä tuotteita tehokkaasti. Kuinka pitkälle kustomointia voidaan viedä?

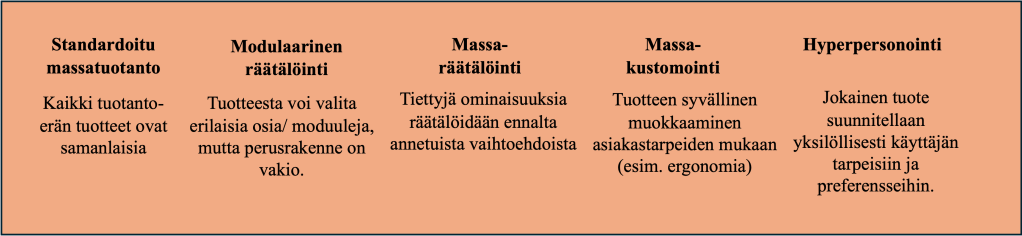

Kustomoinnin tasoja on useita, ja yritykset voivat valita niistä liiketoimintaansa parhaiten sopivan tai yhdistellä erilaisia kustomointimalleja tarjontaansa. Seuraavassa on kustomoinnin viisi päätasoa 3D-tulostuksen näkökulmasta:

- Standardoitu massatuotanto on perinteinen tuotantomalli, jossa kaikki tuotteet ovat identtisiä.

- Kustannustehokas ja skaalautuva, mutta joustamaton asiakastarpeiden suhteen. Massatuotanto ei yleensä sisällä kustomointia. Sen sijaan 3D-tulostus voi mahdollistaa nopeammat prototyypit ja tehokkaamman tuotannon.

- Modulaarinen räätälöinti. Modulaarisessa räätälöinnissä asiakas voi valita tuotteen eri osia, mutta itse tuotteen muoto ja perusrakenne ovat ennaltamääritettyjä.

- 3D-tulostus mahdollistaa joustavien, helposti vaihdettavien moduulien valmistuksen – esimerkiksi erilaisten pidikkeiden, lisäosien tai vaihtokomponenttien valmistamisen nopeasti ja kustannustehokkaasti.

- Massaräätälöinti: Tässä mallissa asiakas voi valita tiettyjä ominaisuuksia ennalta määritetyistä vaihtoehdoista.

- Mahdollistaa suuren volyymin tuotannon, mutta tuo mukaan yksilöllisyyttä. 3D-tulostus tekee massaräätälöinnistä tehokkaampaa, sillä se ei vaadi erillisiä tuotantolinjoja jokaiselle variaatiolle.

- Massakustomoinnissa asiakas saa tuotteen, joka on räätälöity hänen tarpeidensa mukaisesti.

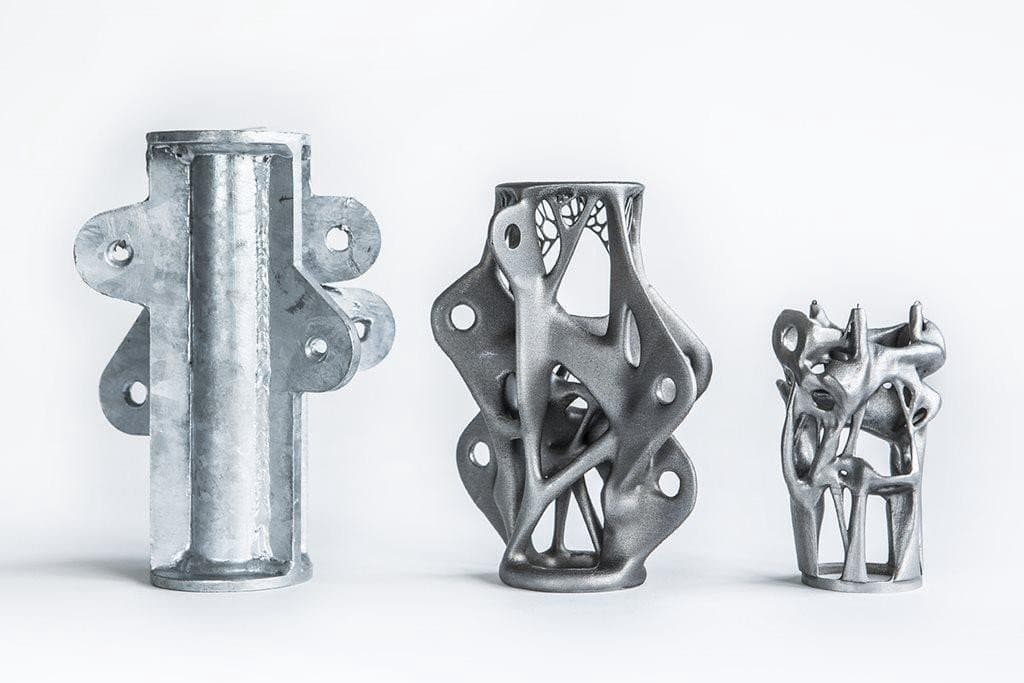

- Tämä voi tarkoittaa esimerkiksi mukautettuja mittoja, ergonomisia muotoja tai yksilöllistä suorituskykyä. Tämä on yksi 3D-tulostuksen suurimmista vahvuuksista, sillä se mahdollistaa täysin yksilöllisten tuotteiden valmistuksen ilman suuria kustannuksia.

- Esimerkki: 3D-tulostetut yksilölliset ortopediset pohjalliset tai urheilijoille tehdyt räätälöidyt kypärät.

- Hyperpersonointi: Tämä on kustomoinnin ääripää, jossa jokainen tuote on ainutlaatuinen ja suunniteltu yksittäiselle asiakkaalle.

- Yhdistää tuotteen ja käyttäjän tarpeet saumattomasti.

- Esimerkki: 3D-tulostetut työkalut tai suojavarusteet, jotka on suunniteltu tekoälyn avulla juuri käyttäjän kehon muotoihin ja tyyliin sopiviksi.

- Tekoäly ja data-analytiikka voivat yhdistyä 3D-tulostukseen luoden tuotteita, jotka kehittyvät ja mukautuvat käyttäjän tarpeiden mukaan.